DIRECT METAL LASER SINTERING

Direct Metal Laser Sintering, abbreviated DMLS, is an established method of additive manufacturing in which metal powders are joined together using a high-power laser. The process is characterized by high accuracy and the ability to produce complex geometries that would otherwise be difficult to produce with traditional machining methods.

When considering DMLS as a company, it is crucial to understand both the technical parameters and the practicalities. The method is not only used in prototype stages but is largely adapted for series production of metal components with high demands on strength and surface finish.

Advantages of DMLS metal

The method provides a number of technical advantages that are important for designers, engineers and purchasing managers. Among the most prominent aspects are:

- High geometric freedom that enables designs with complex structures.

- Good material utilization rate because excess material can be reused.

- Possibility of integrating multiple functions into one and the same component.

These properties make DMLS printing an option when you need to manufacture components that combine low weight, strength and freedom of form.

DMLS printing: the process

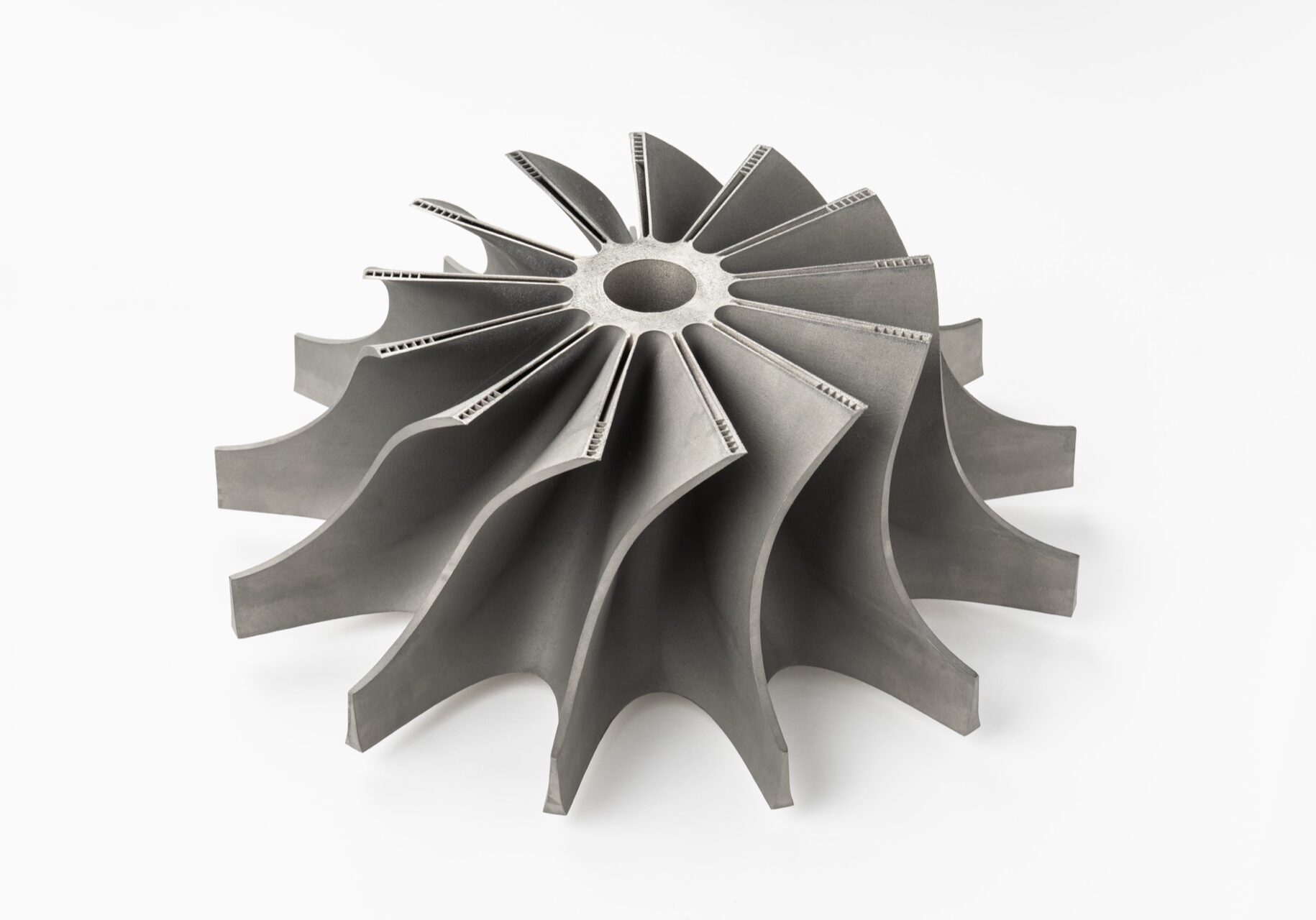

DMLS printing is a method where a thin layer of metal powder is spread over the build platform and a laser melts the areas defined in the CAD model. Layer by layer, the component is built up until the entire part is complete.

The method makes it possible to create geometries that are otherwise difficult to produce, such as internal channels, advanced support structures and detailed surfaces. DMLS metal can be performed with materials such as stainless steel, titanium, aluminum and nickel-based alloys, which makes it possible to adapt the material selection to different industrial needs.

DMLS is a term often used synonymously with SLM (Selective Laser Melting). The internationally accepted standard is LPBF (Laser Powder Bed Fusion). All three terms refer to the same process, but the terminology varies between suppliers and industry standards.

Design and tolerances

When working with DMLS, it is important to take design rules and tolerances into account. Minimum wall thickness, surface smoothness and the possibilities for post-processing are factors that affect the final result. A well-planned design leads to shorter lead times and fewer adjustments in later stages.

To optimize your components, we recommend that the design process be carried out in close collaboration with our technical department. We can provide guidelines on minimum part size, bearing height and support structure requirements.

Post-processing and quality assurance

Components manufactured with DMLS metal often undergo post-processing to achieve the desired surface finish and dimensional accuracy. Common steps include heat treatment, CNC milling, polishing and coating. We ensure that every detail is checked against applicable standards and documented in accordance with industry requirements.

Applications of DMLS

-

Aerospace industry: light and strong structural parts, components in jet and rocket engines, fuel system parts, internal cooling channels.

-

Automotive industry: prototypes of engine and driveline components, lightweight parts for motorsport, tools and fixtures, customized components for premium vehicles.

-

Energy and heavy industry: parts for gas and steam turbines, heat exchangers, spare parts in demanding environments, components for pumps and valves.

-

Electronics and telecommunications: enclosures with electromagnetic shielding, heat sinks, RF components and miniaturized connectors.

-

Tools and mold making: injection molding tools with conformal cooling channels, mold inserts, special tools with complex geometry.

-

Defense and military: light parts for equipment, spare parts for military vehicles, special components for testing and evaluation.

-

Medical technology: orthopedic implants, dental implants, surgical tools and anatomical models for planning.

-

Luxury industry and design: jewelry, watch components, designer accessories and limited editions.

DMLS printing and your future production

As a supplier of metal additive manufacturing, we help you integrate DMLS into your production chain. You gain access to a technology that not only reduces material waste but also helps shorten development times. We support you from the design phase to the finished product and offer advice to achieve the right balance between design, material and post-processing.

For further information about our service and our capabilities, you can read more about 3D printing in metal.

The next step for your business

We encourage you to contact us for a dialogue on how DMLS can be implemented in your processes. Our goal is to create solutions that are tailored to your specific requirements and that provide long-term value in your production. Contact us today to discuss your needs and receive a quote for your project.

Frequently asked questions about DMLS, SLM and LPBF

Are DMLS, SLM and LPBF the same thing?

Yes. All three terms are used for the same process. DMLS is originally a brand name from EOS, SLM is an industry term and LPBF is the international standard.

What materials can be used in DMLS printing?

Common materials include stainless steel, titanium, aluminum, and nickel-based alloys. The choice is guided by the application's requirements for strength, weight, and environment.

Which industries use DMLS?

The method is used in the aerospace industry, the automotive sector, energy and heavy industry, electronics, tool manufacturing, defense, medical technology and design, among other areas.