Manufacturing of components in 316L

Working with 3D printing in stainless steel opens up new methods for producing durable components with high precision. At AM Printservice, we provide solutions where you can order parts in 316L stainless steel adapted for both prototypes and series production. Through additive manufacturing, designs are created that were previously difficult or costly to produce with traditional processing methods.

You can order your 3D print online directly in the digital tool. Please contact us for more information via email to info@amprintservice.com or call us at (+46)10-788 83 50

Rapid prototyping

Strong construction

Complex geometries

Corrosion resistance

What does 3D printing steel mean?

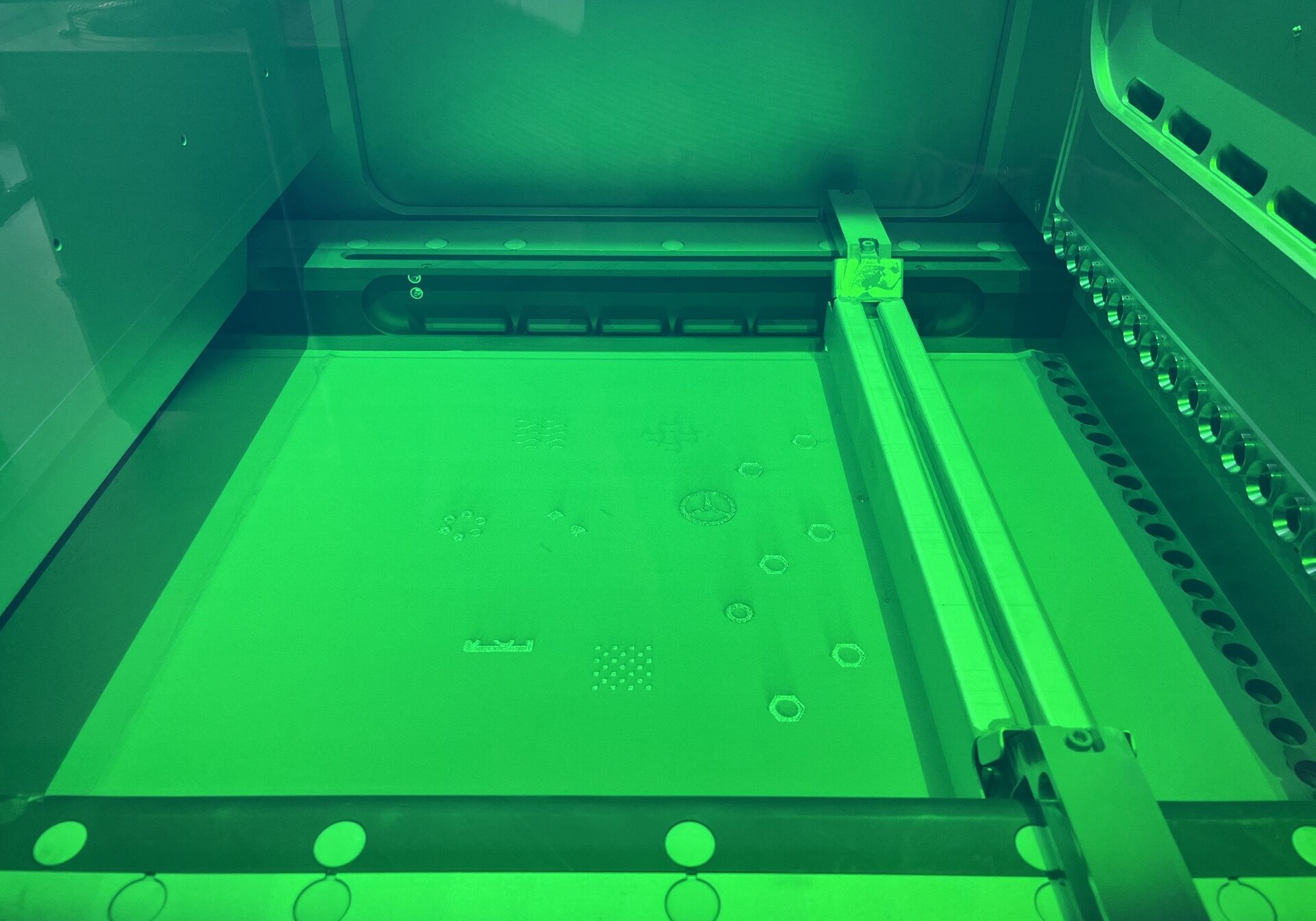

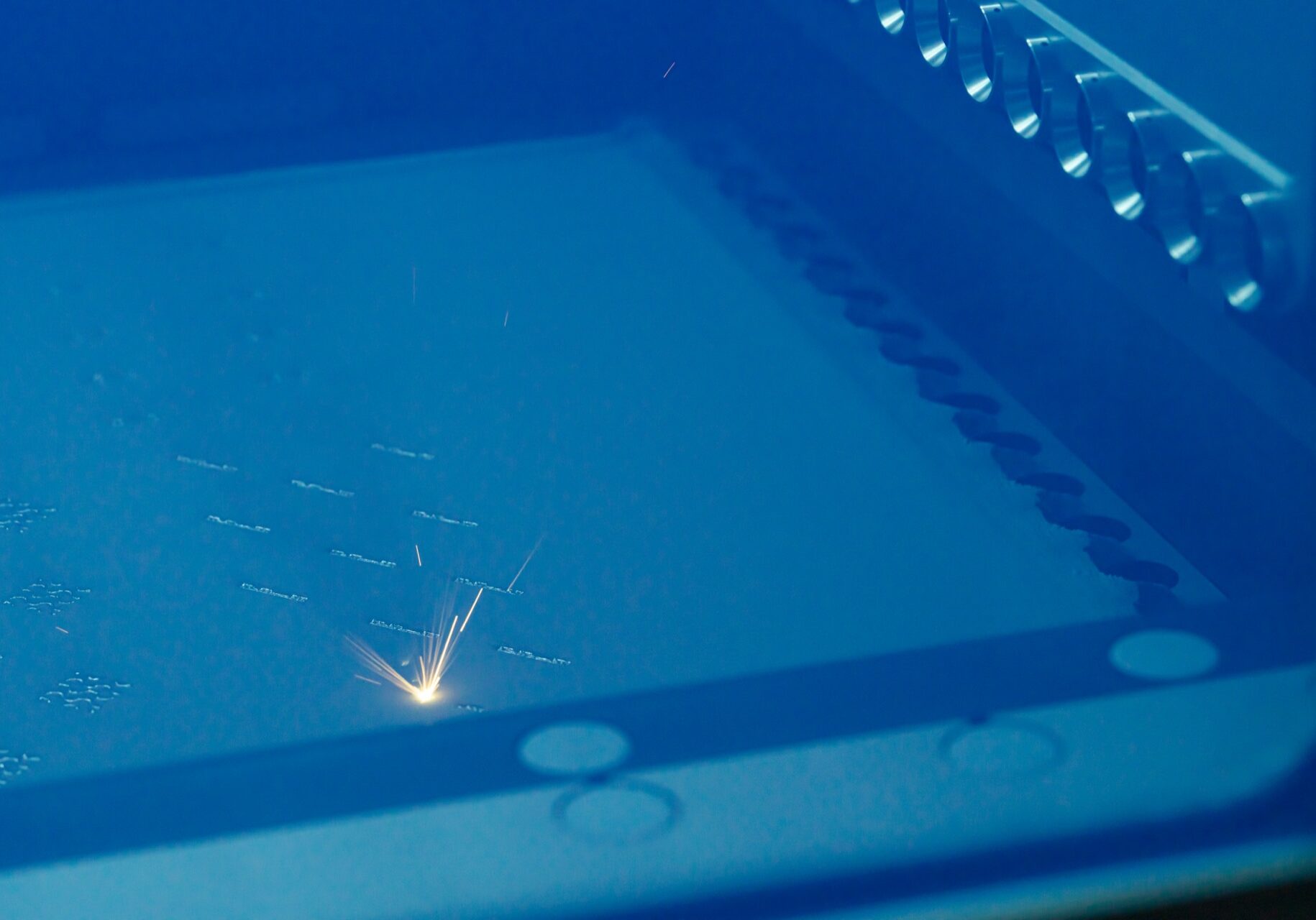

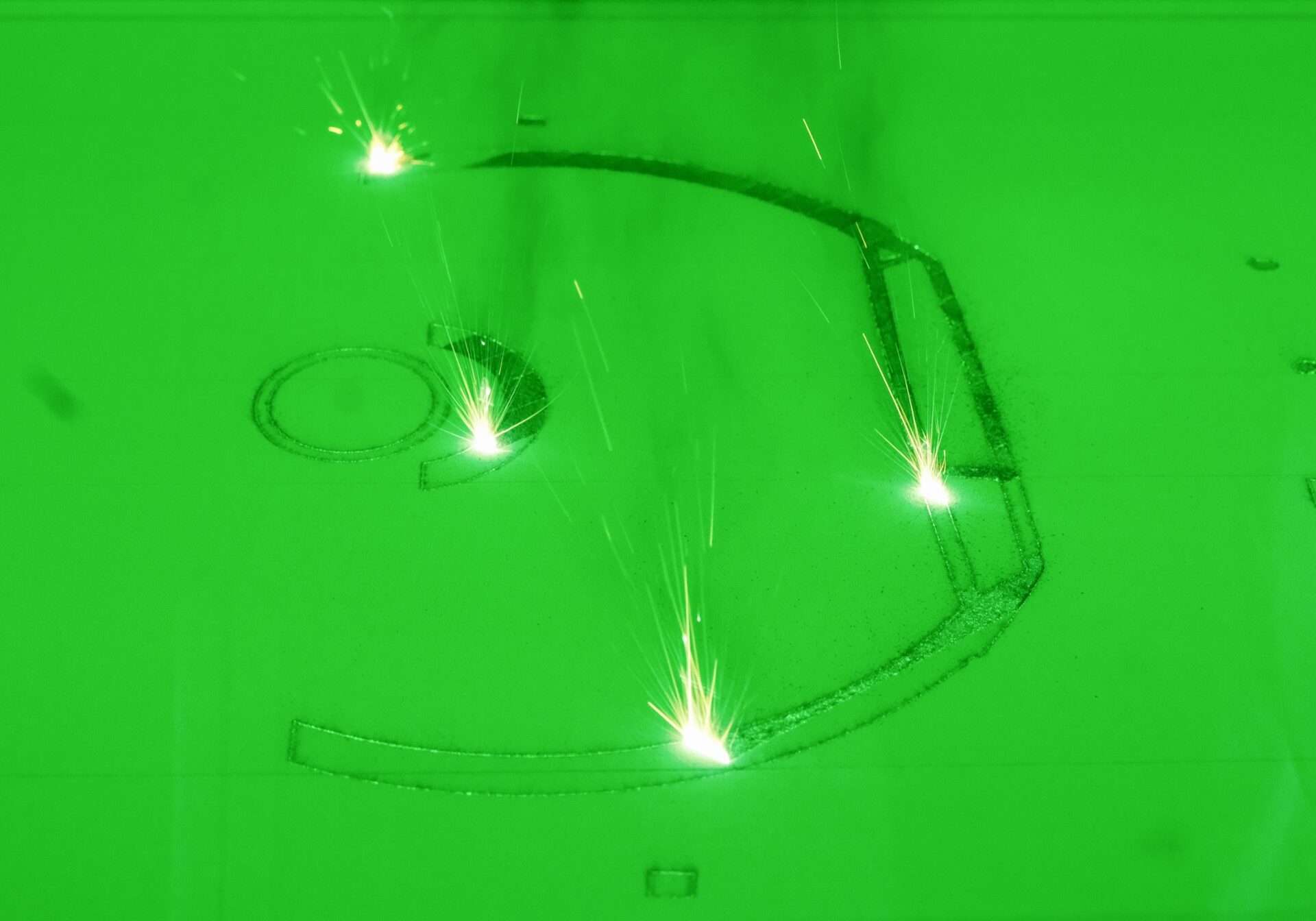

3D printing steel is based on the additive manufacturing technology, where powdered materials are fused together layer by layer using a laser. Unlike conventional processing, where material is removed from a larger object, only the volume required is built up here. This makes the technology resource-efficient and provides access to new design possibilities.

By 3D printing steel, we can produce parts with internal channels, geometries that otherwise require costly assemblies, and structures that reduce weight without compromising strength. This makes manufacturing more flexible and can be adapted to project-specific needs.

Advantages of 3D printing steel

Additive manufacturing in metal makes it possible to produce complex geometries and optimize weight ratios without compromising the strength of the material. Stainless steel is a material that combines mechanical strength with resistance to corrosion. When we use 3D printing steel we can achieve:

- Geometries with internal channels and features that cannot be manufactured with conventional machining.

- Reduced material consumption because only the volume required is built up.

- Faster path from idea to finished product, which shortens development cycles.

These factors help you streamline processes and improve your production chain.

316L stainless steel in additive manufacturing

Among the stainless steel alloys used in 3D printing, 316L stainless steel is one of the most sought after. The alloy contains molybdenum and nickel, which provides excellent resistance to chlorides and acids. This makes it suitable for components in the chemical industry, marine environments and medical applications.

When we print in 316L stainless steel, its toughness and weldability are preserved, while the additive processes allow for freedom of design. The result is components that can be customized to meet both strength and hygiene requirements.

Quality controls and process data

Our production in 3D printing steel is based on established process parameters that ensure dimensional accuracy and reproducibility. We work with layers at the micron level to achieve defined tolerances. Post-processing by shot blasting, heat treatment and polishing is used to achieve the desired surface structure.

By following documented quality controls, we can deliver products that meet your technical requirements. We provide material certificates and data from each run so you can verify the properties of each individual component.

Applications for 3D printing in stainless steel

Stainless steel is suitable for a variety of industries where strength and durability are crucial. Examples of applications include:

- Components for equipment in food and pharmaceutical production.

- Machine parts exposed to high mechanical loads and corrosive environments.

- Prototypes for design validation with the same characteristics as the final products.

By utilizing 3D printing in stainless steel, you gain access to solutions that both reduce lead times and create opportunities for more advanced design.

Collaboration and support through AM Printservice

We at AM Printservice work closely with you as a customer. You can easily upload your CAD files via our print on demand and receive a quote. In addition to manufacturing, we offer advice on design for additive production, choice of post-processing and material selection.

By combining our technical expertise with a flexible approach, we can support you from early development to finished components. Our goal is to provide you with access to knowledge and solutions that create added value for your business.

Contact us

If you are considering 3D printing in stainless steel or have a need for components in 316L stainless steel, we are ready to assist. By contacting us, you can discuss requirements, receive technical advice and take advantage of our production capabilities.

Take the initiative today and let us together ensure that your projects are realized with the highest possible precision and reliability.